Aquatic Pelleted Feed Vs Extruded Feed - Which Is Best for Fish

Aquatic Pelleted Feed Vs Extruded Feed -

Which Is Best for Fish

In the past years, aquaculture industry has

developed with great speed, which has also given rise to the wide applications

of aquatic feed industry. aquatic-feed1Specially designed for aquatic animal

breeding, aqua feed can be divided into fish feed, shrimp feed and crab feed

according to feeding varieties, divided into pelleted feed and extruded feed on

the basis of production process, and divided into mixed feed, concentrated feed

and premixed feed in the light of fodder features. The raw materials of aquatic

feed are mainly constituted of fish meal, cereal materials and grease,

thereinto the previous two always account for over 50% of feed cost. Because

fish have small intestines and stomach, lack of good digestion and absorption

ability, the requirements on processing technique of fish feed are far higher

than that of livestock feed, so it’s particularly important to choose suitable

production process and equipment.

As is well known, aquatic feed production

development has been through several phases, including hand feeding process,

cold forming of moist diets, pelleting presses via pellet milling technique and

extrusion technology via feed extruder. Currently, pellet feed and extruded

feed have become two main popular fish feed due to the profits they bring for

fish farmers. Here, FANWAY, as the pioneer of various fish feed machines

professional manufacturer, will discuss the respective manufacturing processes,

advantages and disadvantages of both pelleted fish feed and extruded fish feed.

Contrast of Pelleted Feed & Extruded

Feed

With the development of processing craft,

fish feed can be produced as pelleted feed and extruded aqua feed. Compared

with natural feed, they have higher density and less humidity, not only

allowing for long time reserve but decreasing the isolation of raw and

processed materials. Although these two aquatic feeds have the same

ingredients, there are obvious differences after put into water: pelleted feed

sinks in water bottom while extruded feed floats on water within certain time

due to their physical characteristics. Even if with the same formula, the cost

of extruded aqua feed is higher than that of pelleted feed, but extruded feed

can still create more benefits in virtue of its remarkable advantages.

1.Manufacturing process

aquatic-feed-manufacturing-processThe

principle of choosing raw material is to select the lowest cost in the premise

of ensuring that feed contains the required nutrient substances. In addition,

choosing materials should be based on the upper limit and lower limit dosage of

ingredients probably used as raw materials, stipulating the upper limit dosage

of materials with natural toxins and the lower limit dosage of some materials

so as to improve the palatability and water stability of fish feed. For

instance, feed producers should control the floor level of rice vermicelli

processing by-products and other starch-type materials in order to promote the

cohesiveness and stability in water of feed pellets while providing energy.

Besides, the thinner the particle size of

raw materials, the higher the digestive utilization ratio, and the better the

cohesiveness and water stability of fish feed. Remember to dilute and add the

mineral premix compound before crushing and the vitamin premix compound after

crushing step by step.

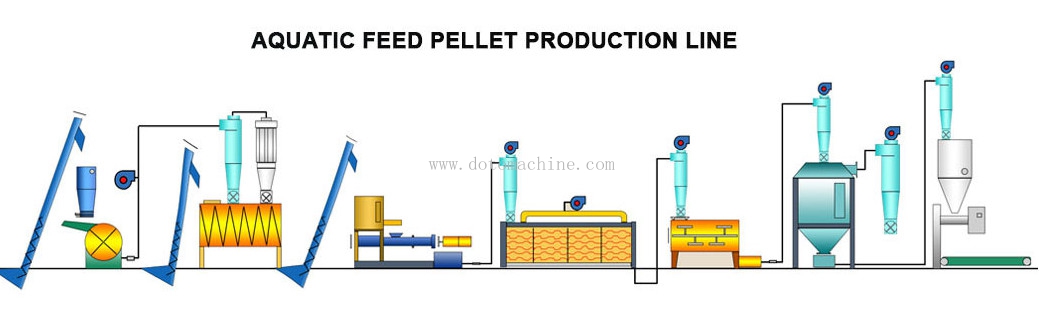

As to their manufacturing processes, FANWAY

concludes as the following figure shows. Clearly, the difference between these

two aquatic feed is the third step, that is, pelleted feed mainly uses

pelleting mill technique while extruded feed chiefly adopts extrusion technology

via high-performance fish feed extruder. In contrast, the processing craft of

extruded fish feed is more complicated.

2.Advantage & disadvantage of pelleted

aqua feed

As far as production is concerned, pelleted

feed has a series of advantages, such as low cost investment, high yield, low

unit production charge, fast capital return and so on. Moreover, compared with

natural food and unprocessed grain feed, pelleted feeds via pelleting press are

easier to store, package and transport. For fish farmers, pelleted feed has low

price but high feed coefficient, which not only makes major cultured fish (like

grass carp, crucian and cyprinoid, etc.) grow well but also bring mixed culture

fish (like silver carp and dace, etc.) good growth.

Well, as the saying goes, every coin has

two sides, pelleted feed also has some obvious shortcomings. To be specific,

it’s hard for feed plant to earn money if demand is not enough big because of

the low unit profit. What’s worse, pelleted feeds sink a litter faster after

cast in water, which is too late to eat for fishes, so many of them fall to the

bottom. Statistically, there are about 10%-15% pelleted feed wasted due to the

fast sinking, heavily polluting water quality, affecting the ecological

environment and increasing

aquatic-feed3

feed cost as well. Meanwhile, lots of

nutrients are dissolved under water, resulting in the lower of mixed feed

original quality, all of which have become the prominent problems at the aspect

of aquatic feed technology.

3.Merit & demerit of extruded fish feed

Nowadays, extruding technology is very

common and widely used in producing kinds of feed. In fact, various fishes

should be fed according to feeding habits of different fishes, broadly

separated into three categories - floating, sinking and slow sinking, and feed

should stay in water completely for certain time so as to fish have enough time

to eat. For now, only by using extruding technology can achieve the above

features. With the incomparable superiority, the extruded fish feed has low pollution,

high efficiency, high conversion, playing a vital role in the improvement of

digestive utilization ratio.

During extruding process, heat, humidity,

pressure and various mechanism actions can enhance the starch gelatinization

degree, damage and soften the cell wall fraction of fiber structure and release

some begirt digestible substance, thus boosting the digestion and utilization.

During extruding process, moderate heat

treatment can passivate some proteinase inhibitor (like antitryptase or urease),

eliminate the side effect, kill harmful germs in raw materials and change the

property of protein molecule to increase contact with enzyme in fish body,

which makes feed easier for fish to digest.

Extruded feed can lower the content of

cottonseed and gossypol dramatically, bringing better detoxification effect.

Meanwhile, its long time stability in water, up to 12-36hours, makes it

convenient to observe and control fish feeding.

Certainly, there are always two faces to

everything, and it’s without exception for extruded aquatic feed. Although

extruded aquatic feed has distinct preponderance than pelleted aqua feed and

its manufacturing process gains acceptance from lots of feed plants, its

initial investment of production line is much larger, which also scares many

feed enterprises or fish farmers.

Option of Pelleted Feed & Extruded Feed

The option of aquatic feed should consider

the feeding characteristics and habits of different aquatic livestock. For

instance, river crab and other benthic animals are accustomed to search food in

water bottom and eat food very slow, so aquatic feed for them cannot be too

hard, and the loss of fragment caused by biting food should be reduced as far

as possible. aquatic-feed2Then extruded sinking feed would be a better choice

because it is convenient to soften and suitable to gnaw, reducing feed waste

and water pollution with less fragment loss. Moreover, extruded aquatic feed

has long water resistant time and high cultivated degree. Additionally, when

the aquatic products market condition is well, using high-class pelleted feed

or extruded feed can fatten fish quickly for selling on market as soon as

possible. Feeding with those aquatic feed cannot only lower the occurrence rate

of fish disease and make fish taste better, but also decrease waste of

resources under the condition of fishing resources starvation day by day.

However, using extruded feed through whole

feeding process can also lead to feed/meat ratio rising, bad sensitivity and

intolerant for long distance transport. In adult fish phase, still continuing

to use extruded fish feed can cause fish guano, big fish tripe and high

moisture content in body so that customers are not willing to purchase.

In a word, during the process of fresh

water aquaculture, the mixed using of pelleted feed and extruded feed can not

only regulate water quality and reduce fish feed waste, but also improve the

output of aquatic products, achieving the perfect combination of water quality

control and economic benefits. Therefore, the combination of pelleted feed and

extruded feed is the most significant feeding mode deserving to promote so far.

Company News

Contact us

- Jinan Datong Machinery CO.,LTD

- 0086-18653342336

- 0086-88085286

- foodmachinery@hotmail.com

- Gaohanji Industrial Park,Tianqiao area,Jinan city,Shandong province china